Why are StarRC SPEF files required in Ansys Redhawk for IR Drop Analysis? (Even Though It Has Parasitic Extraction Capabilities)

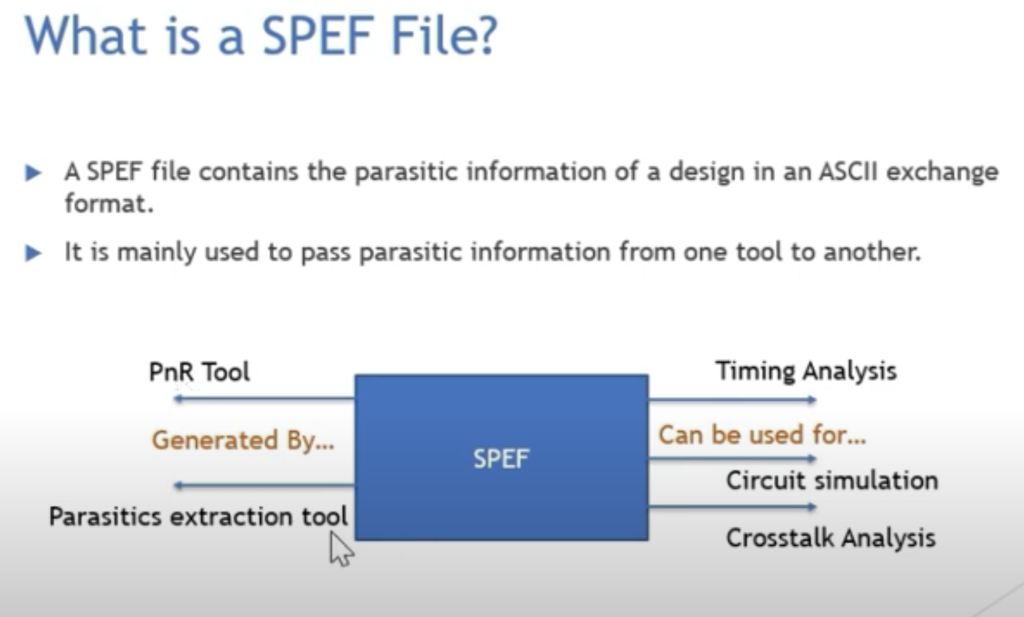

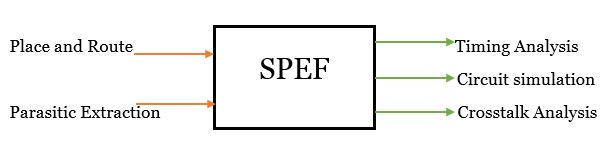

Ansys Redhawk is a powerful tool for power integrity (IR drop) and electromigration (EM) analysis, but it still relies on Standard Parasitic Exchange Format (SPEF) inputs for several critical reasons:

1. SPEF Provides Accurate Post-Layout Parasitics

Redhawk’s Built-In Extraction vs. SPEF:

Redhawk can estimate parasitics, but SPEF files from signoff-quality extraction tools (e.g., StarRC, Quantus) are more accurate because:

-

- They account for process variations (corner-specific RC).

-

- Include detailed coupling capacitances (Cc) and distributed RC networks.

-

- Capture metal density effects (e.g., chemical-mechanical polishing (CMP) variations).

Example Scenario:

If Redhawk estimates parasitics internally, it may miss localized resistance/capacitance hotspots that SPEF captures from a full extraction flow.

- Capture metal density effects (e.g., chemical-mechanical polishing (CMP) variations).

2. Consistency with Signoff Timing Analysis

SPEF Ensures Correlation with STA:

-

- Static Timing Analysis (STA) tools (e.g., PrimeTime) use SPEF for delay calculations.

-

- Using the same SPEF in Redhawk ensures IR drop analysis aligns with STA results.

Risk Without SPEF:

- Using the same SPEF in Redhawk ensures IR drop analysis aligns with STA results.

- If Redhawk uses its own extraction, IR drop-induced delays may not match STA predictions, leading to mismatches in timing signoff.

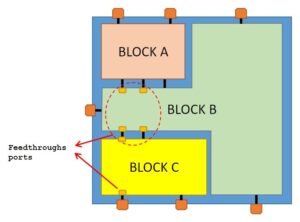

3. Handling Hierarchical and Mixed-Signal Designs

SPEF Supports Hierarchical Abstraction:

-

- For large SoCs, SPEF files provide black-boxed or reduced-order models of macros (e.g., SRAMs, analog blocks).

-

- Redhawk’s internal extraction may not handle hierarchical partitioning efficiently.

Mixed-Signal Designs:

- Redhawk’s internal extraction may not handle hierarchical partitioning efficiently.

- SPEF includes analog parasitics (e.g., substrate coupling) that Redhawk’s digital-centric extraction might miss.

4. Redhawk’s Role: Power Network Analysis, Not Extraction

Redhawk’s Core Strength:

-

- Focuses on dynamic IR drop, EM, and power noise rather than parasitic extraction.

-

- SPEF lets Redhawk offload extraction to dedicated tools (StarRC, Quantus) while specializing in power integrity.

Performance Trade-off:

- SPEF lets Redhawk offload extraction to dedicated tools (StarRC, Quantus) while specializing in power integrity.

- Extracting parasitics on-the-fly in Redhawk would slow down analysis for large designs.

5. SPEF Enables Cross-Tool Validation

Golden Reference for Debugging:

-

- If IR drop issues arise, engineers can compare SPEF-based Redhawk results with other tools (e.g., Voltus, PrimePower) to isolate inaccuracies.

Example Workflow:

- If IR drop issues arise, engineers can compare SPEF-based Redhawk results with other tools (e.g., Voltus, PrimePower) to isolate inaccuracies.

graph LR A[Layout (DEF/LEF)] --> B[StarRC/Quantus] B --> C[SPEF] C --> D[Redhawk IR Drop Analysis] D --> E[Signoff]

When Does Redhawk Use Its Own Parasitics?

Redhawk can estimate parasitics in limited scenarios, such as:

-

- Early Exploration (pre-layout, rough estimation).

-

- Missing SPEF (with reduced accuracy).

-

- Partial Updates (small ECOs where full re-extraction isn’t needed).

However, for signoff-quality IR drop analysis, SPEF remains mandatory.

Standard SPEF extraction (e.g., StarRC) often excludes PG nets by default since they’re typically handled by dedicated power integrity tools.

We use SPEF with signal nets only and let RedHawk extraction engine compute the parasitics extraction for PG nets, which for sign-off is recommended to use RedHawk’s extraction engine.

However, if needed, you can also force StarRC to include PG nets:

# Enable PG net extraction in StarRC config (EXT.conf)

PRESERVE_PG_NET_NAMES : YES

EXTRACT_PG_NET_GEOMETRY : YES

EXTRACT_PG_NET_CC : YES # Captures coupling caps

# Generate SPEF with PG nets

write_parasitics -format SPEF -output design_pg.spef -include_pg_nets

However, RH extraction engine is better for this, make sure to use the PG nets option in RH.

# In RedHawk (or Fusion Compiler with RedHawk engine)

analyze_power_network -extraction_engine redhawk -power_ground_nets {VDD VSS} -dynamic

Key Takeaways

Always use corner-specific SPEF (e.g., maxRC for worst-case IR drop).

| Reason | Why SPEF is Better |

|---|---|

| Accuracy | Signoff extraction tools model RC more precisely. |

| STA Correlation | Ensures IR drop and timing analysis agree. |

| Hierarchical Support | Handles macros/black boxes efficiently. |

| Performance | Lets Redhawk focus on power analysis. |

| Debugging | Cross-tool consistency checks. |

Regarding using IPF or Instance power Format file from PrimePower, the general recommendation is to start with PrimePower IFBS/IPF, then refine with RedHawk for IR-aware updates.

RedHawk should improve power estimates compared to PrimePower, as RedHawk adjusts power calculations based on local IR drop and temperature, while PrimePower assumes nominal voltage.

So while PrimePower gives better cell level accuracy, RedHawk provides better IR/ Thermal Aware results.

Seeing large Delta between StarRC extraction versus manual hand calculations?

Readers Ask:

The Resistance number for simple RDL routing [bump to IO pad] extracted by STAR-RC shows significant delta [35%] compare to manual calculation [R = sheet resistance * L/W]. What could be the reason or solution?

Our Experts answer:

1) Regarding the 40% delta between StarRC vs manual calculation, it appears that StarRC might be using a different Sheet resistance value than your manual calc. due to difference in process corner/ Temp. or layer specific adjustments.

Have you tried to report layer properties in StarRC?

report_layer_rc -layer RC -corner ss

Compare Rho with manual value.

2) Another issue could be Via Resistance:

– StarRC includes via resistance (bump-to-RDL and RDL-to-10-pad bias), which manual R = p • L/W ignores.

• A single via can add 0.1-29 depending on size/stacking.

# Report via resistance from tech file

report_via_resistance -via_type VIA1

3) Another solution to try is to extract effective resistance using Redhawk which is better at computing for RDL resistance and also accounting for parallel paths, if any.